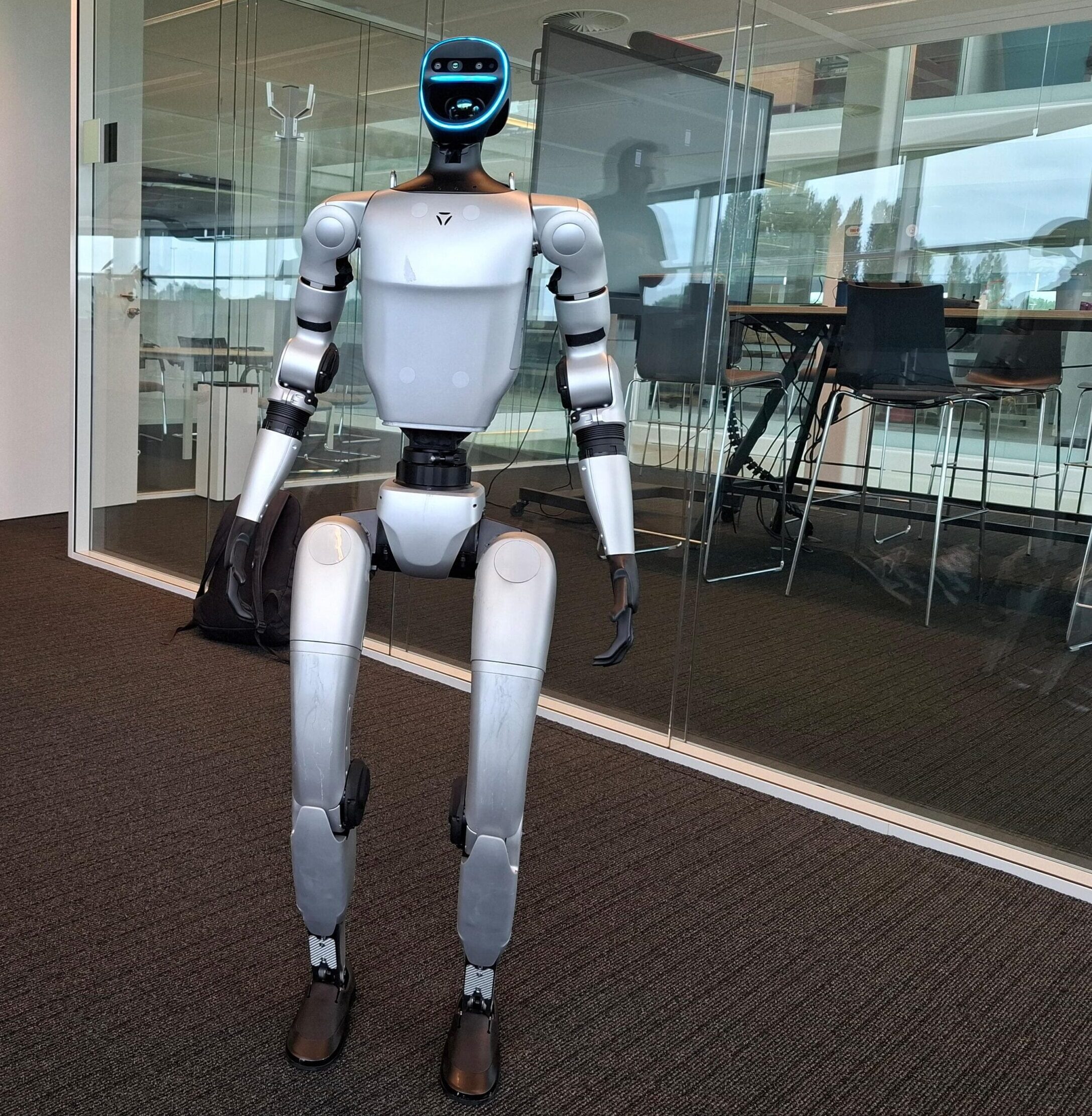

The Dutch greenhouse horticulture sector is facing a pressing challenge: while the workload continues to increase, skilled labour is increasingly scarce. There is no shortage of tasks, only of hands to do them. How can we ensure that productivity and sustainability remain safeguarded? The Telegreen project may offer an answer: a collaboration between academia and companies developing an innovative humanoid arm that will support employees and secure the future of the sector.

Duration

January – December 2025

Partners (TU Delft)

Partners (other)

Societal value

With the TeleGreen project, company Look-E explores how remote robot control can enhance flexibility and efficiency in greenhouse horticulture. It could also widen workforce participation, offering opportunities for those unable to work on-site. Without rigid, pre-programmed routines, operators can react quickly to changing conditions. Tasks such as harvesting and inspection could then be carried out remotely with the same situational awareness and adaptability as if the operator were physically present in the greenhouse.

5G

Developing a teleoperation system to allow operators to perform tasks remotely, especially in tomato harvesting is part of this experiment. To achieve this, robotic arms are controlled over a private 5G network in a real, functioning greenhouse: Tomatoworld. This kind of wireless connection is essential since, compared to public networks, it provides the high speed, low latency, and enhanced security needed for real-time control.

5G allows the system to support two-way video and haptic feedback, a technology that lets users feel tactile sensations. This is essential for harvesting and inspection, where flexibility and situational awareness are essential to avoid damaging the crop. Robotics takes on the heavy, delicate, repetitive tasks, while 5G ensures instant, reliable communication between all systems.

Tailored solution for greenhouses

However, the true innovation lies not only in the seamless integration of robotics and ultra-fast connectivity. Many existing high-tech teleoperation systems focus on other industries and overlook greenhouses. And while robotic systems are already in use in greenhouses, few offer real-time remote control. This limitation is most evident in complex tasks that require humanoid manipulators to work in dynamic environments, such as manoeuvring through rows of plants. The TeleGreen project aims to bridge this gap by providing a solution tailored to the unique needs of greenhouse environments. It distinguishes itself by combining several key elements, such as an open infrastructure to make the system easily adaptable, and advanced robotics to handle complex, delicate tasks.

The project could set a new standard for the remote management of greenhouses. And in doing so, it demonstrates how technology can transform agriculture for the future.